Flight data solutions are improving avionics and enhancing aircraft safety. Here’s Excalibur Systems’ take on flight data analysis and components.

Flight data solutions is a blanket term for equipment and technologies used in an aircraft to acquire, process, analyze, and utilize flight data that help manufacturers and operators ensure a safe and efficient flight. While flight data systems primarily work towards maintaining standard operating procedures (SOP), they have a much larger and more important role in enhancing aircraft and consumer safety.

Flight data analysis helps aircraft safety in two ways. One, by identifying an aircraft’s operational safety risk which involves pitting its real-time avionics data with flight data recording of previous flights. Metrics are compared with pre-defined reference points to understand deviation, if any. Next, a flight’s digital data acquisition unit uses this comparative data to take necessary actions to prevent potential safety risks. Statistical analysis allows the system to understand if a potential safety risk needs any corrective action and then pushes for it.

Since the early twentieth century when first flights began operation primarily for military use, flight data acquisition has been an integral part of aviation. Since then, tremendous advances in the field have helped flight systems become more sophisticated to mitigate risks. Today, with the rise of artificial intelligence (AI), flight data solutions have taken a larger leap in helping flight operators fly with less stress, rare accidents, and more efficiency.

Here’s a rundown of modern flight data solutions and how they help enhance aviation safety.

Origins of Flight Data Solutions in the Twentieth Century

The first flight data solutions—during the Second World War—were basic real-time flight data recorders (FDR) used to measure metrics like airspeed and load factor. The focus was always on improving an aircraft’s load factor as the military required them to carry as much goods as possible. These metrics were collected and analyzed to improve the structural design of aircraft in production.

The first FDRs were made of metal foils on which numbers and other information would be engraved during the flight. As the years passed, FDRs began recording more information such as altitude, time, and acceleration. This is when flight data solutions first began to be installed in commercial flights for post-accident investigation. If the military used flight data analysis to improve structural design, flight data recording became a key motivation for safety in commercial flights. By the 1960s, aviation regulation came into force, making flight data acquisition mandatory for most types of aircraft.

While the first FDRs recorded metrics on tape, technology evolved and gave rise to digital recordings (on tape) and then solid-state devices. All sorts of data began to be collected, with at least one estimate showing that over 3,000 different metrics were recorded using flight data solutions. Black boxes, a type of FDR, today are the most critical components for an aircraft accident investigation. The modern flight data recorder has undergone a radical change since the 1940s.

Over the years, flight data analysis has evolved into a technological marvel. Today, aircraft safety and accident investigation are the major mandates of flight data recording systems. As is expected, a lot of it depends on the equipment that make up an airborne data acquisition system.

With today’s strict regulations, the demand from FDRs and allied products has peaked and so have the challenges. It’s not just enough to record data and use it in an iterative process to ensure safety. There are compliance requirements set by regulators that aircraft manufacturers and carriers have to abide by if they want to operate smoothly. Global FDR policies are outlined and governed by the International Civil Aviation Organization (ICAO) as well as the respective regulatory bodies of countries. In the United States, the Federal Aviation Authority (FAA) oversees the technical and safety aspects of commercial and military flights.

Other than the technical requirements, the FDR instruments are also supposed to be rugged enough. They must withstand shock, extremely high and low temperatures, high pressure (especially undersea), and water immersion. This is to ensure that in case of an accident, the FDR system (or the black box) can be retrieved safely. Interestingly, black boxes are colored in vivid orange for better visibility during recovery, which is again a compliance requirement.

All of this points to the need for high-precision flight data solutions that are not only technically sound but also robust enough to meet the compliance criteria.

Flight Data Recording: Key Instruments and Methods

Since flight data is primarily used to prevent accidents, and if they do happen, investigate why they did, flight data solutions are conditioned in a certain way. The reactive-proactive-predictive (RPP) model forms the base of this condition, where the idea is to have historical data for reference and comparison, real-time monitoring of aircraft activities, and a predictive system dependent on real-time data gathering while the aircraft is in flight.

The proactive and predictive systems are largely influenced by standards and instruments within the aircraft. The entire flight data acquisition unit (FDAU) is made up of various devices that continuously sense and record data, eventually coordinating with each other to provide critical information to the operators as well as guides at large. There are also cockpit voice and flight data recorders (CVFDR) that are in high demand as they combine extraction of cockpit sound and equipment data. CVFDR is one of the most critical components of any aircraft as far as safety is concerned. Not to mention its technology advancing rapidly and requiring vendors to improve their products further for seamless integration.

In an ideal scenario, the best way to prevent accidents is for flight data solutions to jump into the predictive process without waiting for the first two iterations (reaction and proactive action). Predicting a deficiency in the aircraft before it fails is the key aim of any kind of flight data solution.

Assisting aircraft and its operators in this process is a host of analog, electronic, and integrated products like protocol converters, real-time flight data recorders, bus analyzers, and testers. The most important of these products are the recorders that are designed to extract information from various communication protocols such as ARINC-429 and MIL-STD-1553 simultaneously and pass that information to other devices for processing and relaying.

Advanced Flight Data Solutions from Excalibur Systems

- One of the key proprietary products in the field is the MARC II Mini Recorder from Excalibur Systems, a lightweight flight data recorder that is capable of recording information from dozens of different avionic communication protocols and storing that data in its solid-state memory. It is the latest version of our flagship product MARC which was designed as an avionics translator more than 10 years ago. The MARC II system has a memory of 64 GB and an integrated heatsink that has low-to-no influence on nearby instruments. As a leader in the field of avionics instruments, Excalibur Systems has been manufacturing and delivering rugged flight data solutions equipment.

MARC II - Mini Recorder | Excalibur Systems

- The 1553 Bus Analyzer from Excalibur Systems is another simple, portable device that can be used to monitor and record 1553 bus traffic using a simple Windows interface. There’s also the 429 Bus Analyzer for capturing and analyzing real-time ARINC-429 traffic.

Portable Rugged 1553 bus analyzer | Excalibur Systems

Portable 429 bus analyzer | Excalibur Systems

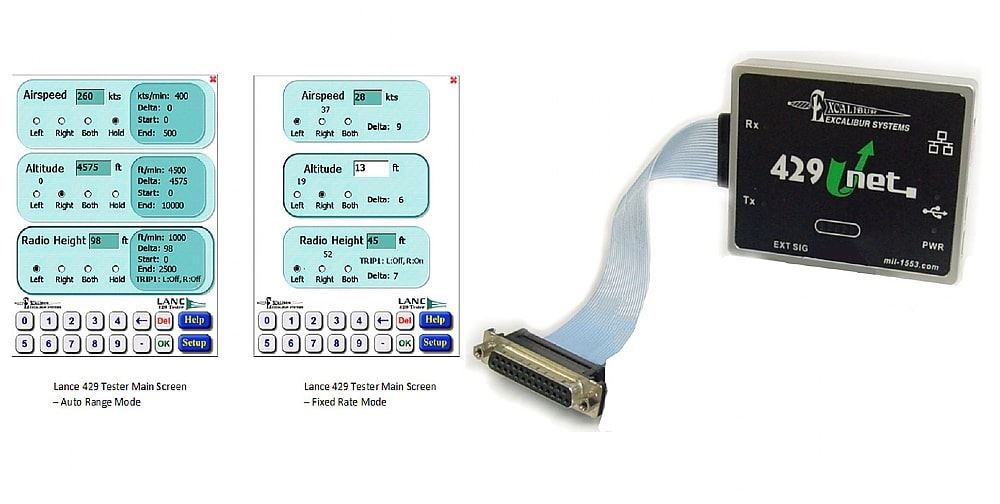

- Other notable Excalibur Systems products include the ARINC-429 tester and Flight Simulator Testing System. Both these systems are simulators that allow you to test out avionics that depend on the ARINC-429 bus and need integration with modern form factors like PCI Express ports. The portable nature of these testing units gives an added advantage to engineers who can use a single system to customize their testing.

Arinc 429 Tester | Excalibur Systems

- Helping operators integrate these equipment to create an advanced flight data system are instruments like the Dragon Rugged PC/104 System that act as a bridge between devices operating under different standards and technologies. The products are aircraft-agnostic, which means one system can be used to test out any type of aircraft as long as the parameters to be tested are the same.

Dragon - Rugged PC/104 System | Excalibur Systems

- The Flight Simulator Testing is beneficial specifically for improving 1553 cybersecurity. Since MIL-STD-1553 is considered outdated, the idea is to strengthen other components that communicate with it, thereby adding a security later between all transmissions. This is one way to shield an avionics system based on the 1553 standard from cyberattacks.

Flight Simulator Testing System | Excalibur Systems

A key area is in the way Excalibur Systems products are designed. They not only meet the technical working requirements of aircraft manufacturers and operators but also compliance requirements. With decades of experience handling avionics equipment, Excalibur Systems is the preferred partner in the United States and outside.

Need for High-Precision Flight Data Solutions

Flight data recorders and associated equipment require high precision due to the amount and urgency of the data that is handled. This demands the flight data recorders to be low-maintenance equipment that can perform perfectly day in and day out. The same applies to flight data processing, which is a tedious process of converting raw aircraft data into readable material. In most cases, analogous information is relayed to analog-to-digital converters (ADC) and then transmitted. A combination of parameters is then analyzed to detect potential risks and deficiencies.

Finally, the processed digital flight data is combined with manual reports shared from other sources (like the operator, for instance) to create various scenarios. Analysts study these scenarios to detect serious concerns related to aircraft and its safety, and start corrective actions when needed.

Since the core of this whole flight data analysis process is dependent on flight data recorders and allied components, there is an urgent need for high-precision instruments—especially in military aircraft—that can provide high-quality outputs.

Using Data Analytics and AI in Flight Data Solutions

While high-precision equipment handles flight data recording, how the recorded data is used and implemented to improve flight efficiency and safety is another important part of the process. Advanced flight solutions now make use of data and predictive analytics to cut through the clutter and find useful bits from the sea of information.

Data analytics has the power to decode patterns and correlations in recorded data that can be used in real time to assist in flight management and even air traffic control. The combination of historical and real-time data, as noted above, is ever-critical for safety management. Analytics tools help create models that can forecast and schedule maintenance timelines, predict component failures based on their age and ratings, and uncover potential operational failures.

The biggest advantage of using data analytics in avionics is that it works according to individual aircraft’s unique behavior as opposed to acting on averages. Since not all flights are the same and there are always differences in load and other parameters, predictive analytics is very well poised to enhance aircraft safety in the coming years.

With its series of precision flight data recording products, Excalibur Systems is continuously innovating to offer tangible flight data solutions to its customers so that they can integrate analytics into their current FDR systems.

Advanced flight data solutions have already begun influencing how aircraft are manufactured and operated by airlines and military carriers. With the recent rise in gaps in safety protocols by leading manufacturers, regulators have tightened the need for compliance and security protocols from manufacturing to maintenance to operation. All of this puts part of the onus on component manufacturers like Excalibur Systems to continue to innovate and design lightweight and rugged airborne data acquisition systems that perform well for longer periods without the need for regular deep maintenance.

Are you looking for high-quality flight data solutions that will fit perfectly with your future-ready avionics ecosystem? Get in touch today.